How Does A Lawn Mower Engine Work? How to Fix It?

by Lee Safin

We are very familiar with a lawnmower, but how many of us use it regularly?

So the burning question is “how does a lawnmower engine work?”

When you pull the rope to start the lawnmower manually, it starts to spin the engine. This forces air and fuel into the engine. This air and fuel enter through the carburettor responsible for regulating the right amount of air and fuel mixture to pass through.

The flywheel rotates along with the engine when you pull the rope. As the flywheel spins and passes over the ignition coil, it creates a magnetic field. The spark plug gets electricity voltage because of this magnetic field.

The spark plug ignites the mixture of air and fuel. This creates an explosion controlled and drives the piston rings in motion that rotate the crankshaft.

Then comes a long winter, and when in spring you decide to shape up your garden, you find that the old machine won’t start.

This article will tell you exactly, “How Does a Lawn Mower Engine Work?” and how to fix a lawnmower.

For those still unfamiliar with a lawn mower’s functions, it is a machine used to cut grass and other plants in the garden grounds in an even shape.

Usually, the grass’s height to the surface is adjustable, but sometimes it may be fixed by the operator.

Moreover, if you are looking for the best lawn mower for a small yard, check the linked article. We found out some best of the bests.

Contents

- How Does a Lawn Mower Engine Work?

- Basic Components

- How Does a Lawnmower Engine Work? – In Brief

- Important Facts of a Lawnmower Engine

- The Price of Rebuilding a Lawnmower Engine

- Possibility of Using a Push Mower Engine on a Riding Mower

- The Estimated Lifespan of a Lawnmower Engine

- The Most Common Lawnmower Problems and Reasons (White smoke)

- How Does an OHV or Four-stroke Engine Lawnmower work?

- Lawnmower Engine Problems and Symptoms

- In Case of a Blown Engine, Should You Rebuild or Buy a New Lawnmower?

- Lawnmower Carburetor Troubleshoots and Maintenance – How to Fix a Lawn Mower

- Signs of a Bad Carbonator

- Exhaust

- Overheating and Engine Backfiring

- Difficulty While Starting

- How to Access The Carburetor?

- How to Clean the Carburetor

- How to Clean The Carburetor Without Removing It?

- Final Cleaning of The Carburetor

- Conclusion

How Does a Lawn Mower Engine Work?

So we are going to discuss from the very basic “how does a lawnmower engine work?” Before point that we need to know about the basic components of a lawnmower engine.

Basic Components

A lawnmower engine is similar to a motorcycle, but the parts are much smaller and manageable.

The different parts that work together in a lawnmower engine are as follows:

Carburettor

The carburettor is responsible for regulating the mixture of air and fuel that should flow into the engine. The amount of airflow and fuel depends on the terrain you are on, the speed, and how long your engine operates.

If you are looking for a carburettor for your “MTD Murray M20300 500E 21″ 22” Lawn Mower” then we recommend this one.

Spark Plug

Everyone who owns a vehicle of any sort is aware of what a spark plug is. This device is responsible for igniting the fuel and air mixture passing into the engine. The thread size of lawnmower spark plugs is from 10mm to 12mm.

If you are looking for a spark plug for your lawnmower “Briggs & Stratton Genuine 491055S” then we recommend this one.

Flywheel

The flywheel spins along with the engine and helps keep momentum so that the crankshaft is in motion in between the engine’s power strokes. You should buy the replacement according to the model of your lawnmower.

Ignition Coil

The ignition coil helps generate a magnetic field and coordinates the time for the spark so that the air and fuel mixture in the engine is ignited in the combustion chamber.

If you are looking for a spark plug for your lawnmower “Stens 440-450 Ignition Coil” then we recommend this one.

How Does a Lawnmower Engine Work? – In Brief

Now in a brief, we will see “how does a lawnmower engine work?”

When you pull the rope to start the lawnmower manually, it starts to spin the engine. This forces air and fuel into the engine.

This air and fuel enter through the carburettor responsible for regulating the right amount of air and fuel mixture to pass through.

The flywheel rotates along with the engine when you pull the rope. As the flywheel spins and passes over the ignition coil, it creates a magnetic field. The spark plug gets electricity voltage because of this magnetic field.

The spark plug ignites the mixture of air and fuel. This creates an explosion controlled and drives the piston rings in motion that rotate the crankshaft.

The flywheel has fins attached, so it also acts as a cooling fan.

Moreover, if you are looking for the best lawn mower for a small yard, check the linked article. We found out some best of the bests.

Important Facts of a Lawnmower Engine

The Price of Rebuilding a Lawnmower Engine

Is it worth rebuilding a lawnmower engine?

It is a frequently asked question with no definite answer. It depends on the type of lawnmower you are using, the model, and how damaged your current lawnmower is.

This article will help you understand the mechanism of a lawnmower, and with the proper knowledge, you will be able to decide the best solution for it.

The cost of repairing a lawnmower varies from place to place. Sometimes the cost of repairing a lawnmower can exceed the price of the product itself. In these cases, it is very unwise to get the engine rebuilt. It is better to get a new machine.

After a proper diagnosis of your lawnmower, if you find that the repairs can be done quickly by exchanging a few faulty parts and lubricating the machine properly, go for the repair.

Possibility of Using a Push Mower Engine on a Riding Mower

An engine is an object capable of powering a machine, whether it is a push mower, riding mower, or bike. However, engines are of two types. One is a vertical shaft, and the other is a horizontal shaft.

If you can manage to transmit the engine’s shaft rotation to the riding mower’s input shaft, you will be able to use the push mower engine in a riding mower to some extent, depending on the engine power.

You will need to keep several things in mind when connecting a push mower engine to a rider. First and foremost is the horsepower (HP) of the machine. Riding mowers require a lot of HP and the largest engine of a push mower is only 6.5 HP, which is insufficient for riding mowers. You may be able to ride the mower, but it will be difficult for the rotary blades to function efficiently.

You will also face difficulties in adjusting the diameters of the crankshaft and bolt patterns.

The Estimated Lifespan of a Lawnmower Engine

The life expectancy of a lawnmower depends on the manufacturer and proper maintenance. On average, a lawnmower lasts for 500 to 600 hours.

However, I have often come across old farmers who have been using their lawn mowers for more than 25 years, to say 1500+ hours. The reason may be that back then, the lawnmowers were better manufactured.

Various other factors shorten the life span of a lawnmower engine. For example, how often you use the lawnmower, the length of the grass that you cut. If you cut long grass routinely, then the life expectancy will decrease.

Do not purchase a new lawn mower because your old one has passed the life expectancy. With proper maintenance and the necessary replacement of inexpensive parts, your old lawn mower can surprise you.

Moreover, if you are looking for the best lawn mower for a small yard, check the linked article. We found out some best of the bests.

The Most Common Lawnmower Problems and Reasons (White smoke)

White or blue smoke coming out of your lawnmower engine usually means that there is oil burning somewhere in your engine, usually where the fuel is supposed to fire.

There are various reasons for oil to be burning in your engine.

Why Your Lawn Mower is Leaving White Smoke?

- Filling too much oil in your crankshaft will cause it to spill around in your engine.

- You are using the wrong oil grade at a different temperature. The chart below will tell you which oil grade is suitable for what temperature.

- Your crankcase breather in the lawnmower is not operational.

- Your lawn mower’s head gasket may have blown.

- The cylinder and rings in your lawnmower may be worn.

When you operate your mower on a surface with a slope of more than 15 degrees, your engine’s oil spills also causing white smoke.

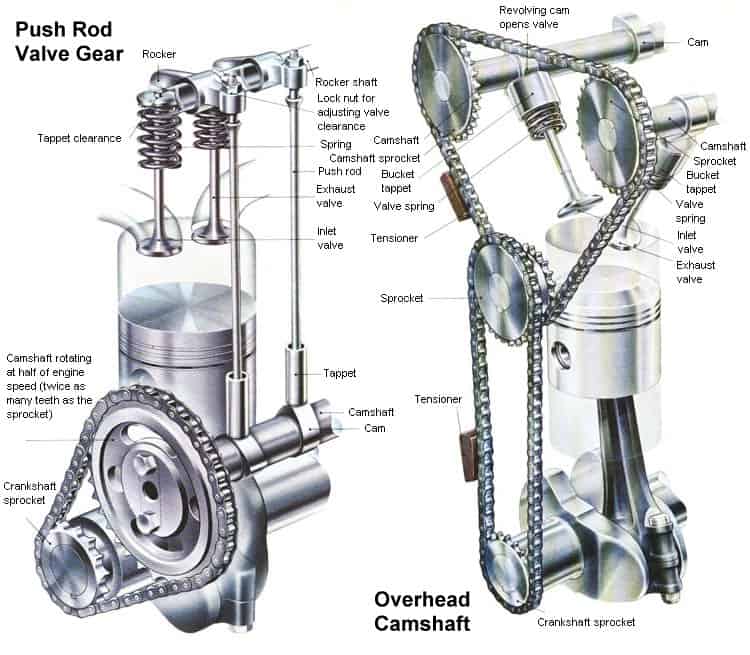

How Does an OHV or Four-stroke Engine Lawnmower work?

OHV or overhead valve engines are 4-stroke and more efficient. They allow the mixture of air and fuel to spread more evenly in the combustion chamber. Just like most engines, this too starts with the intake of air and fuel. The carburettor supplies the necessary air and fuel in the combustion chamber.

The Intake Stroke

This piston in between the combustion chamber and carburettor moves down, creating a vacuum. The intake valve opens, and atmospheric pressure pushes the fuel and air mixture inside.

The Compression Stroke

The intake valve closes, and the piston moves upward, compressing the air and fuel mixture.

The Power Stroke

After the compression stroke, the spark plug ignites the compressed mixture of air and fuel. This controlled explosion pushes the piston down, rotating the crankshaft and propelling the vehicle forward.

The Exhaust Stroke

The piston continues three up and down rotations because of the momentum created in the power stroke. Finally, the exhaust valve is open, and the piston pushes the residue gas from the combustion chamber and prepares it again for the intake stroke.

Lawnmower Engine Problems and Symptoms

A Blown Head Gasket

The head gasket separates the cylinder head and the engine block. It prevents the oil and coolant from mixing and acts as a regulator by sealing the internal combustion system.

Here are specific troubleshooting that will help you to identify if you have a blown gasket.

Engine power is low – There can be various reasons for your lawnmower losing its engine power—wear and tear of parts, lack of oil and maintenance, or a blown head gasket.

The exhaust or engine produces a lot of smoke – since the head gasket seals the internal combustion system, too much smoke in the exhaust is another symptom of a damaged head gasket.

Leakage of oil – If the head gasket in a lawnmower is broken, there will be an oil line around the broken gasket.

A sure way to confirm a blown head gasket when these symptoms are seen is to perform a compression test.

Note

To perform a compression test, you will need a compression gauge. You will find this device in any auto repair shop.

To use the compression gauge, you will have to remove the spark plug and insert the plug hole’s compression gauge.

Hold the throttle and choke, pull the starter 7 to 8 times, or till the reading in the pressure gauge stops.

Bad Piston Rings

The piston rings in the engine control the oil pressure and regulate the engine’s oil consumption.

A sign of lousy piston rings is too much white and grey smoke from the exhaust. Then again, too much smoke from the exhaust is a sign of many other different problems.

Since the piston rings are damaged, the engine’s oil consumption is not regulated, so that the engine will consume excess oil.

In a riding mower, your acceleration will be providing less power than usual. Overall your lawnmower will be performing poorly and will have less power.

In Case of a Blown Engine, Should You Rebuild or Buy a New Lawnmower?

The cost to rebuild a lawnmower engine will vary vastly from region to region.

First, if you hire a professional to fix your mower, then the average cost the repairman will charge is about $45 to $100 for low to medium-end push mowers.

The standard rate will range from $125 to $250 an hour for a high-end riding mower. This rate is leaving aside the price of parts that need to be exchanged.

Usually, it is much cheaper to repair a lawnmower than buying a new one depending on the amount of damage it has and parts that need exchanging.

If you are handy with the tools, then you need to assess the damage first.

Changing a blown engine on a high-end riding mower should cost around $800 to $900.

The cost of repairing the transmission of a riding mower should be from $400 to $500.

To rebuild the carburettor, it should be from $77 onwards.

Moreover, if you are looking for the best lawn mower for a small yard, check the linked article. We found out some best of the bests.

Lawnmower Carburetor Troubleshoots and Maintenance – How to Fix a Lawn Mower

When you use your lawnmower, a certain amount of debris such as twigs, grass cut by the blade eventually ends up in the hood.

During air intake by the carburettor, this debris gets stuck in the filter and clogs the carburettor. A bad carburettor can also be responsible for excess fuel consumption.

It is highly advisable to clean the carburettor every two months, depending on use. You can also clean it once three months depending on seasons when usage is significantly less.

Signs of a Bad Carbonator

Low engine performance is the first symptom of a lousy carburettor because it is responsible for supplying the right mixture of air and fuel to the engine.

Your engine will be having less power consuming more fuel. Rideable mowers will provide sluggish acceleration.

Exhaust

producing black smoke means that the engine is burning too much fuel because it is malfunctioning, providing excess fuel to the engine.

Overheating and Engine Backfiring

A malfunctioning carbonator will be providing the wrong mixture of fuel and air ratio. This will also cause the engine to backfire. Overheating of the engine is very common.

Difficulty While Starting

It will be challenging to start your lawn mower because of a failing carburettor. It can also be because of cold weather making your engine cold.

How to Access The Carburetor?

Depending on the lawnmower manufacturer, the carburettor is usually located at the fuel tank’s top or side.

For basic troubleshooting of your lawnmower, it is always necessary to know your engine and carburettor location.

Note

It is always recommended to turn off your ignition, apply the parking brake, if any, before going for a maintenance check. Apply a gear as well if you have the system; this will act as another brake.

If you have used your lawnmower recently, wait for the engine to cool down before performing any maintenance work.

Look around properly for latches to release the hood (or any other restraining covering) in your lawnmower.

It is straightforward to locate your engine. As I mentioned earlier, the carburettor will either be on the top or side of the engine. So look around in these possible locations.

The carburettor is a square or round filter. It also has holes and slits on the top that will help you identify it.

Alternatively, you can also look for your gas tank and follow the fuel line. The fuel line will be connected to the carburettor.

The fuel line is connected at the bottom of the gas tank by a small clamp. The other end of this fuel line will be connected to the carburettor.

How to Clean the Carburetor

Once you have located your carburettor, check its filter. Often there will be a layer of debris and shoot on the filter. This will prevent airflow through the filter.

Use a screwdriver to disassemble the parts. Keep in mind how they are set since you need to put them back together in the same way.

You can use a vacuum cleaner to blow away the layer of dust. You can also submerge the filter in soap and water and dry it. You will also find a carburettor cleaner for commercial use.

Once you have gone through the filter, check all the connections in the carbonator. The throttle and choke plates of the carburettor can be blocked.

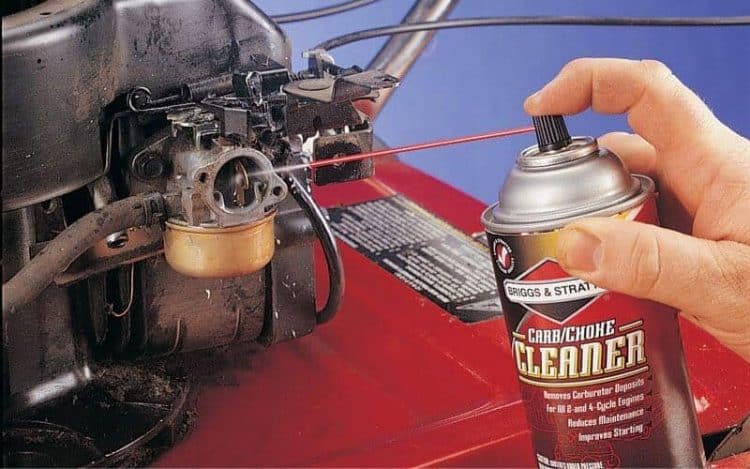

Use a carbonator cleaner to clean any additional dirt that may be clogging the air and fuel passages. You will get carburettor cleaners in spray cans, which will help reach and unblock small air passages.

Assemble the parts and place the carburettor back in its proper place.

How to Clean The Carburetor Without Removing It?

You can also clean the carburettor without eradicating it. Remove the engine covering or hood and get clear access to your carburettor.

Examine the air filters first. Use a brush and carburettor spray to free the filter from any dirt coating debris to allow proper air passage.

Inspect all the connections. Sometimes there might be dirt blocking the pathways. Use an aluminium wire to clear the blockage in small holes. You can use a carb spray to clean the choke shaft quickly.

Final Cleaning of The Carburetor

It would be best if you were careful with this part. Put your lawnmower in neutral with the parking brake on. Now with the hood open, turn on your engine and spray carb cleaner at the centre of the carburettor.

With the engine running, there will be a propelling force. This will make the spray more effective and thoroughly clean the carburettor.

Turn off the ignition and wait for your lawn mower’s engine to cool down before attaching the hood.

Buy on Etsy, eBay, or Walmart

MTD Murray M20300 500E 21″ 22” Lawn Mower - Etsy, eBay

Briggs & Stratton Genuine 491055S - Etsy, eBay

Stens 440-450 Ignition Coil - Etsy, eBay

Conclusion

Now that you have a certain amount of knowledge about “How Does a Lawn Mower Engine Work?” and how to fix a lawnmower.

It will be easier for you to maintain your old machine and help you decide if you should replace it with a new one or fix the old one. Moreover, if you are looking for the best lawn mower for a small yard, check the linked article. We found out some best of the bests.

|

|

|

|

About Lee Safin

Lee Safin was born near Sacramento, California on a prune growing farm. His parents were immigrants from Russia who had fled the Bolshevik Revolution. They were determined to give their children a better life than they had known. Education was the key for Lee and his siblings, so they could make their own way in the world. Lee attended five universities, where he studied plant sciences and soil technologies. He also has many years of experience in the U.S. Department of Agriculture as a commercial fertilizer formulator.

Thoughts on "How Does A Lawn Mower Engine Work? How to Fix It?"

|

|

|

|

Get FREE Gardening Gifts now. Or latest free toolsets from our best collections.

Disable Ad block to get all the secrets. Once done, hit any button below

|

|

|

|